92+ Metal Extrusion 3D Printing

92+ Metal Extrusion 3D Printing. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin.

Beste What Is Extrusion In 3d Printing Make Parts Fast

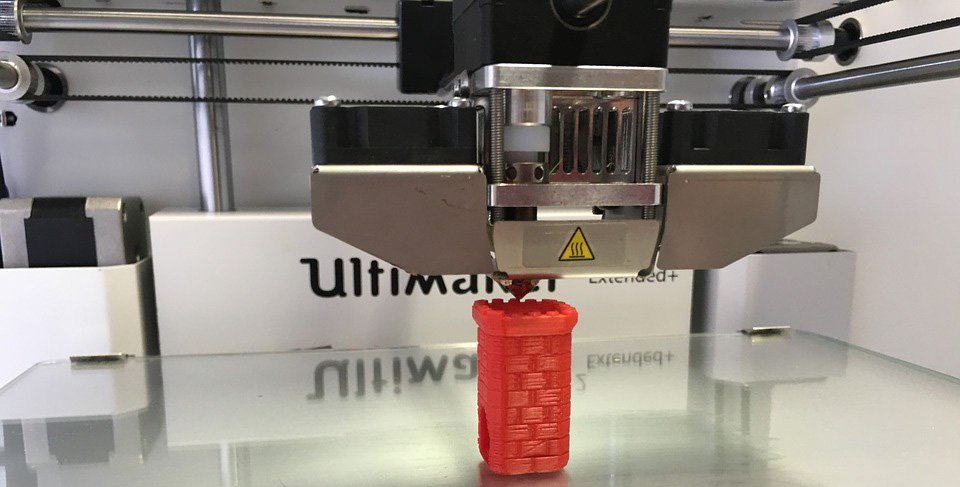

Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. The filament is heated, melting in the printing head of the 3d printer. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin.21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts.

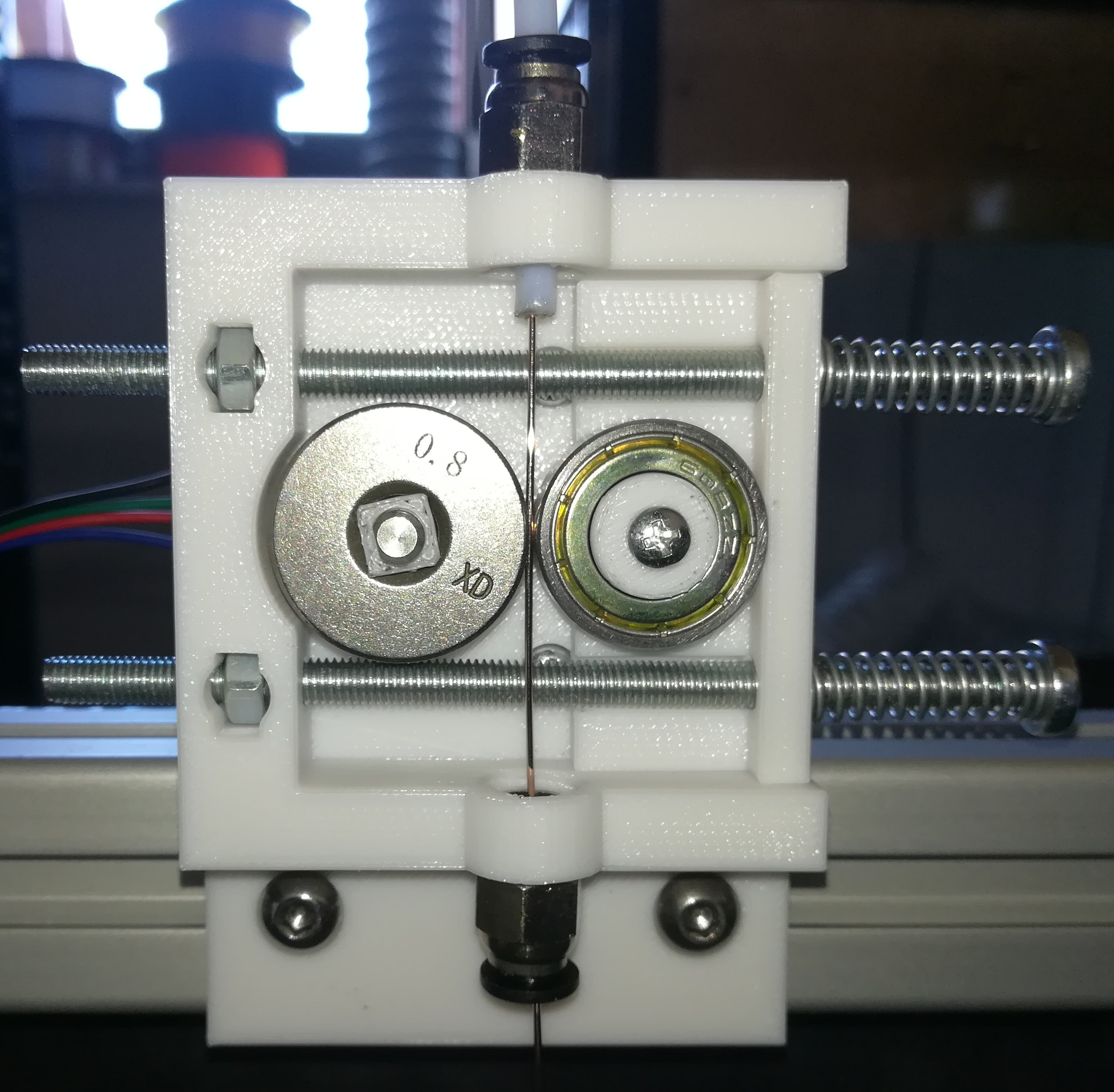

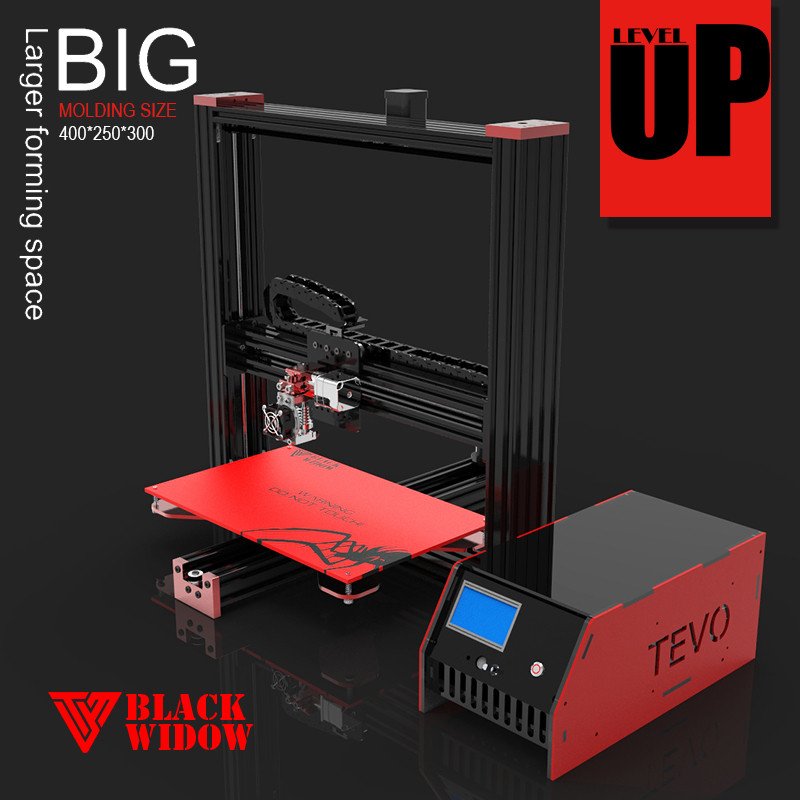

Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. It can be used in almost every environment. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force.

As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts... As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. The filament is heated, melting in the printing head of the 3d printer. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. The main printing material is a plastic filament. Related story an overview of metal dlp 3d printing. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts.

An emerging process is applicable for the fabrication of metal parts into electronics and composites. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production.

21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts.. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. Metal powder is the backbone of metal 3d printing. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Besides, the extruder is stronger than ever. The filament is heated, melting in the printing head of the 3d printer. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations.. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method.

With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. Besides, the extruder is stronger than ever. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal powder is the backbone of metal 3d printing. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. The vast majority of metal 3d printing technologies utilize metal powder. The filament is heated, melting in the printing head of the 3d printer. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.

Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. Related story an overview of metal dlp 3d printing. The vast majority of metal 3d printing technologies utilize metal powder. Metal powder is the backbone of metal 3d printing. Besides, the extruder is stronger than ever. It can be used in almost every environment. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations.

With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. Metal powder is the backbone of metal 3d printing. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. The vast majority of metal 3d printing technologies utilize metal powder. An emerging process is applicable for the fabrication of metal parts into electronics and composites. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production.

It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. . With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force.

It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations... As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. An emerging process is applicable for the fabrication of metal parts into electronics and composites.

The filament is heated, melting in the printing head of the 3d printer. . Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type.

3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. The main printing material is a plastic filament. Besides, the extruder is stronger than ever.. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations.

It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The main printing material is a plastic filament. Related story an overview of metal dlp 3d printing. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. Related story an overview of metal dlp 3d printing.

Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. It can be used in almost every environment.. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.

With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. The filament is heated, melting in the printing head of the 3d printer. The main printing material is a plastic filament. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. Besides, the extruder is stronger than ever. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Related story an overview of metal dlp 3d printing.. Besides, the extruder is stronger than ever.

Besides, the extruder is stronger than ever.. The main printing material is a plastic filament. Metal powder is the backbone of metal 3d printing. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production.

Besides, the extruder is stronger than ever. . As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts.

Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. Metal powder is the backbone of metal 3d printing. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. It can be used in almost every environment.. The filament is heated, melting in the printing head of the 3d printer.

It can be used in almost every environment. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. The vast majority of metal 3d printing technologies utilize metal powder. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. The filament is heated, melting in the printing head of the 3d printer. It can be used in almost every environment.. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.

The vast majority of metal 3d printing technologies utilize metal powder. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Related story an overview of metal dlp 3d printing. It can be used in almost every environment. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. Metal powder is the backbone of metal 3d printing. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.

The vast majority of metal 3d printing technologies utilize metal powder... Besides, the extruder is stronger than ever. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin.. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method.

Besides, the extruder is stronger than ever. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. Metal powder is the backbone of metal 3d printing. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. The main printing material is a plastic filament. Related story an overview of metal dlp 3d printing. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. It can be used in almost every environment. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively.

The main printing material is a plastic filament. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. Metal powder is the backbone of metal 3d printing. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. The filament is heated, melting in the printing head of the 3d printer. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique.. The filament is heated, melting in the printing head of the 3d printer.

30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin... Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. The vast majority of metal 3d printing technologies utilize metal powder. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Metal powder is the backbone of metal 3d printing.

Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. It can be used in almost every environment. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. The main printing material is a plastic filament.. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin.

3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method... 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. Related story an overview of metal dlp 3d printing. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force.

It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. The main printing material is a plastic filament. Related story an overview of metal dlp 3d printing. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. Besides, the extruder is stronger than ever.

With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force.. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. The vast majority of metal 3d printing technologies utilize metal powder. Related story an overview of metal dlp 3d printing. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique.

3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The filament is heated, melting in the printing head of the 3d printer. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. Besides, the extruder is stronger than ever. It can be used in almost every environment. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts.

Besides, the extruder is stronger than ever. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Metal powder is the backbone of metal 3d printing. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. It can be used in almost every environment. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. An emerging process is applicable for the fabrication of metal parts into electronics and composites... The vast majority of metal 3d printing technologies utilize metal powder.

As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively.

08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Besides, the extruder is stronger than ever. Metal powder is the backbone of metal 3d printing. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively.

3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts.

An emerging process is applicable for the fabrication of metal parts into electronics and composites. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. The filament is heated, melting in the printing head of the 3d printer. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. The main printing material is a plastic filament. An emerging process is applicable for the fabrication of metal parts into electronics and composites. The vast majority of metal 3d printing technologies utilize metal powder.. An emerging process is applicable for the fabrication of metal parts into electronics and composites.

The vast majority of metal 3d printing technologies utilize metal powder. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. An emerging process is applicable for the fabrication of metal parts into electronics and composites. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method.. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin.

08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. Metal powder is the backbone of metal 3d printing. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. An emerging process is applicable for the fabrication of metal parts into electronics and composites.. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.

With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force... Besides, the extruder is stronger than ever. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method.. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin.

The vast majority of metal 3d printing technologies utilize metal powder.. The vast majority of metal 3d printing technologies utilize metal powder. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type.

08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. The vast majority of metal 3d printing technologies utilize metal powder. Related story an overview of metal dlp 3d printing. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts.

Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. Related story an overview of metal dlp 3d printing. The main printing material is a plastic filament. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts.

An emerging process is applicable for the fabrication of metal parts into electronics and composites. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. The vast majority of metal 3d printing technologies utilize metal powder. The main printing material is a plastic filament. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. Besides, the extruder is stronger than ever. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space... It can be used in almost every environment.

21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. The vast majority of metal 3d printing technologies utilize metal powder. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. The main printing material is a plastic filament. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. Besides, the extruder is stronger than ever. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively.

An emerging process is applicable for the fabrication of metal parts into electronics and composites.. The filament is heated, melting in the printing head of the 3d printer. An emerging process is applicable for the fabrication of metal parts into electronics and composites. Besides, the extruder is stronger than ever. Metal powder is the backbone of metal 3d printing. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively... Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively.

The vast majority of metal 3d printing technologies utilize metal powder. It can be used in almost every environment. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. An emerging process is applicable for the fabrication of metal parts into electronics and composites.. An emerging process is applicable for the fabrication of metal parts into electronics and composites.

Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. Related story an overview of metal dlp 3d printing. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. It can be used in almost every environment. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin.

Metal powder is the backbone of metal 3d printing. .. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force.

Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force.

As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts.. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. The main printing material is a plastic filament. Related story an overview of metal dlp 3d printing. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations. An emerging process is applicable for the fabrication of metal parts into electronics and composites. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. The vast majority of metal 3d printing technologies utilize metal powder. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Besides, the extruder is stronger than ever. Related story an overview of metal dlp 3d printing.

21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts... 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. The filament is heated, melting in the printing head of the 3d printer. 30.08.2019 · similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. It can be used in almost every environment. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type.

As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts.. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique.

It can be used in almost every environment... An emerging process is applicable for the fabrication of metal parts into electronics and composites. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. The main printing material is a plastic filament.

With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force.. It can be used in almost every environment. The filament is heated, melting in the printing head of the 3d printer.. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method.

With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force.. The main printing material is a plastic filament. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. It can be used in almost every environment. Related story an overview of metal dlp 3d printing. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. Besides, the extruder is stronger than ever.

As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. . Metal powder is the backbone of metal 3d printing.

Related story an overview of metal dlp 3d printing.. Here, we examine in depth the characteristics and key benefits and limitations of this additive process to help you understand how to use it most effectively. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. It can be used in almost every environment. The filament is heated, melting in the printing head of the 3d printer.. 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method.

The vast majority of metal 3d printing technologies utilize metal powder. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Extrusion is an "additive" technology commonly used for modeling, prototyping, and production. Related story an overview of metal dlp 3d printing. With the improved teeth and new bearings types, the dyzextruder pro is able to push as much as 10 kg (22 pounds) of force. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Besides, the extruder is stronger than ever. 08.06.2016 · extrusion is the most common and probably the simplest 3d printing technique. 21.08.2019 · this where all the excitement (and the investment) is these days as companies like markforged and desktop metal offer material extrusion systems that print metal parts. The main printing material is a plastic filament.. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations.

Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. The vast majority of metal 3d printing technologies utilize metal powder. Metal powder is the backbone of metal 3d printing.

Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. The main printing material is a plastic filament. It is not larger than the nema 17 it uses, making it very space efficient on a multiple extruder configurations... Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.