Collectie 190+ Esun Pla Plus Stringing

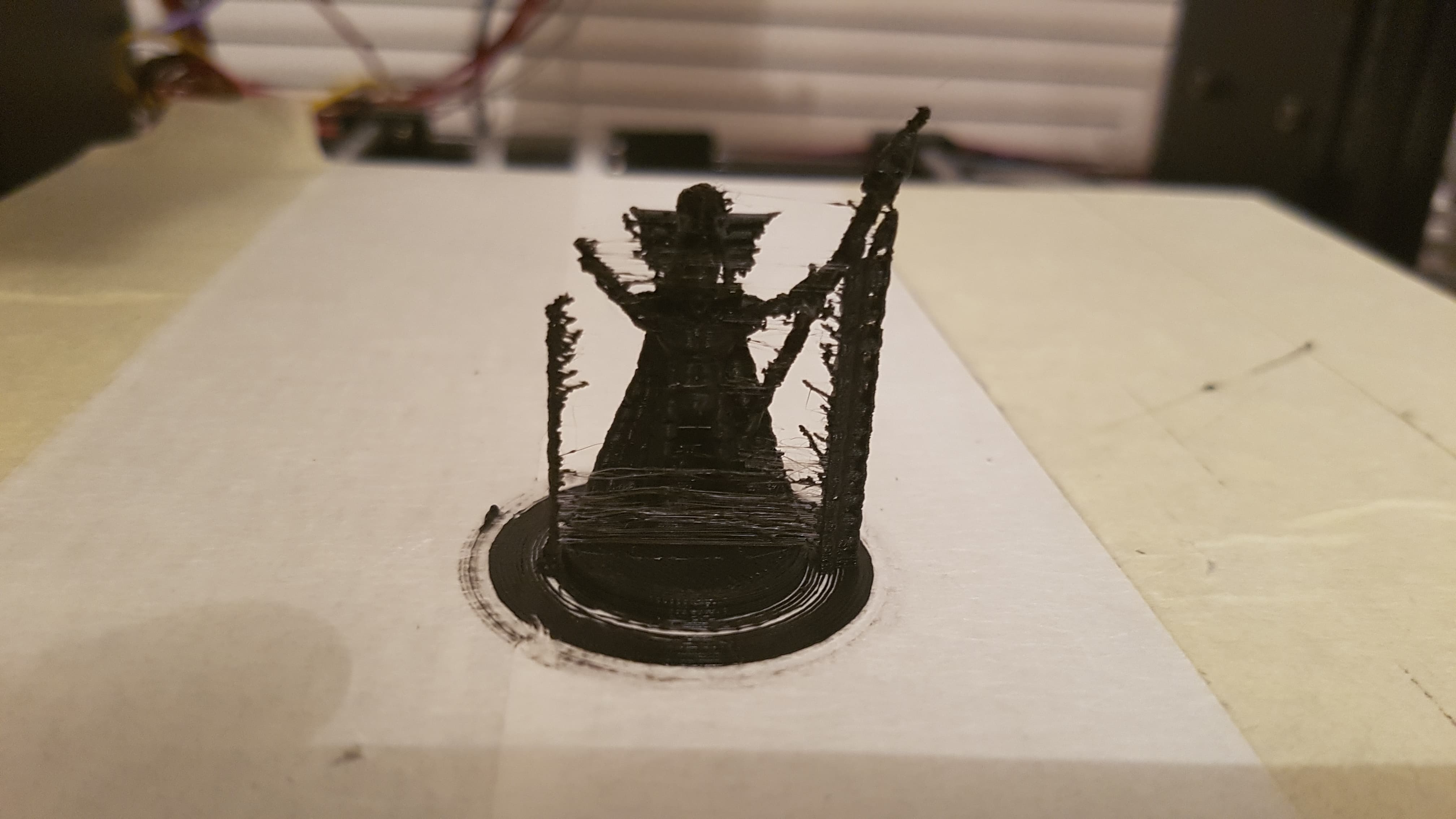

Collectie 190+ Esun Pla Plus Stringing. Filament is esun pla+ white. Slicer i'm using is latest version of cura. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. My basic settings in cura are: My printer is the ender 5 pro.

Beste Esun Pla Plus Pla 1 75mm 1kg Spools Starting From 15 50 Tiztec

Pla is hydroscopic and absorbs water; Setting unload speed at start to 120mm/s. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. My printer is the ender 5 pro.My printer is the ender 5 pro.

No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. Esun pla+, ender 3 v2, and constant stringing. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. I've done the basics such as lowering … No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. Reducing the drag on the filament as much as possible.

No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing... I use esun pla+ and is working really good for me... So like the title says this is what i'm working with (ender 3 v2 and esun pla+).

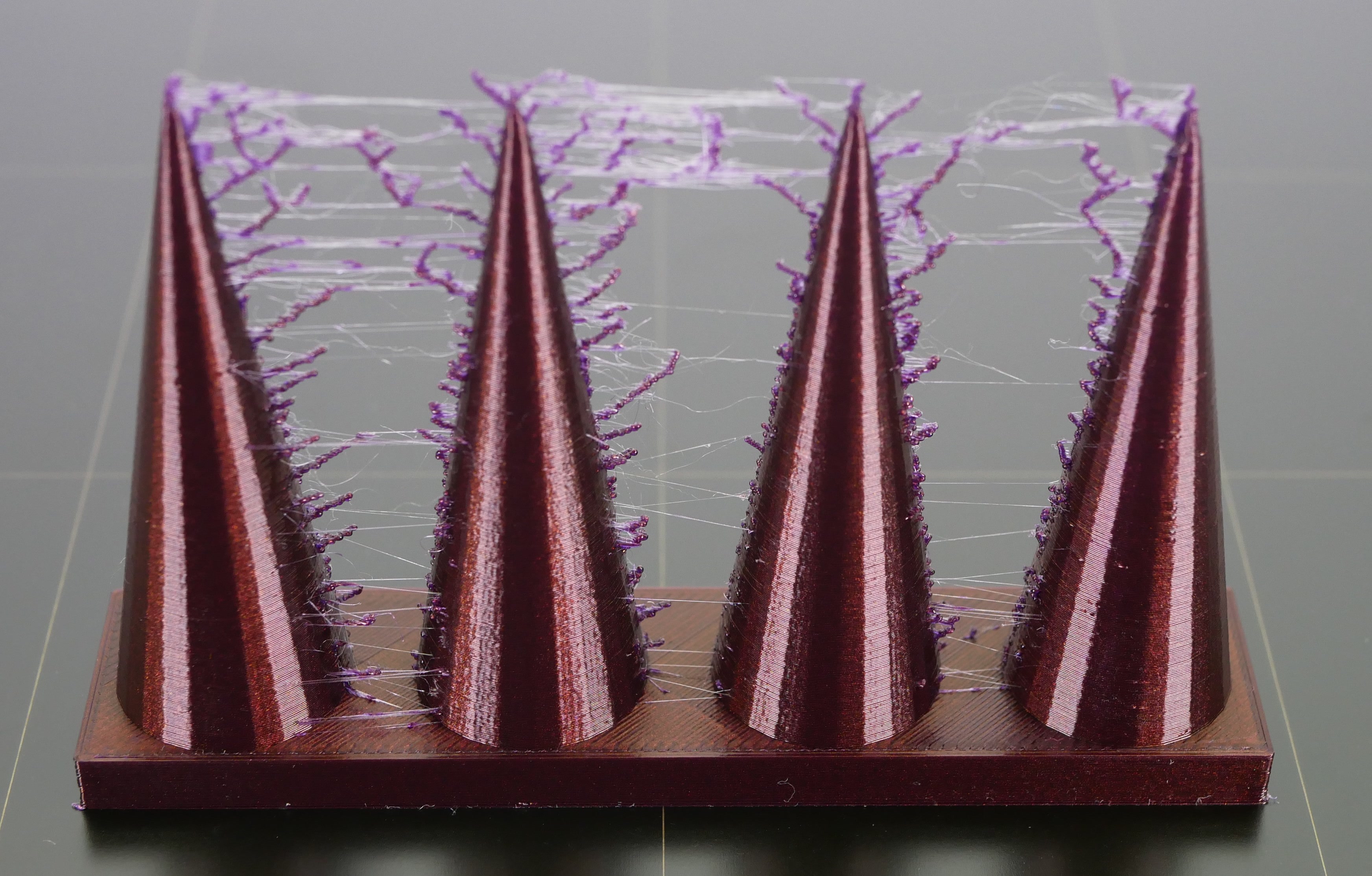

The tower i chose stepped at 190, so i didn't have a... I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). Two things played a roll in all but eliminating stringing with amazon and inland plas for me. Esun pla+, ender 3 v2, and constant stringing. 60, retraction 4,5 mm, retraction speed: Slicer i'm using is latest version of cura. 60, retraction 4,5 mm, retraction speed:

Reducing the drag on the filament as much as possible. Reducing the drag on the filament as much as possible. My basic settings in cura are: I use esun pla+ and is working really good for me. I've done the basics such as lowering … Esun pla+, ender 3 v2, and constant stringing. Setting unload speed at start to 120mm/s. 60, retraction 4,5 mm, retraction speed: I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. Setting unload speed at start to 120mm/s.

Hotend temp 210, bed temp: Esun pla+, ender 3 v2, and constant stringing. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. Hotend temp 210, bed temp: Pla is hydroscopic and absorbs water; My printer is the ender 5 pro. Reducing the drag on the filament as much as possible. 60, retraction 4,5 mm, retraction speed:. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing.

Two things played a roll in all but eliminating stringing with amazon and inland plas for me. Setting unload speed at start to 120mm/s. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. Pla is hydroscopic and absorbs water; The tower i chose stepped at 190, so i didn't have a. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. My basic settings in cura are: Two things played a roll in all but eliminating stringing with amazon and inland plas for me.. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool.

No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. Reducing the drag on the filament as much as possible. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. I've done the basics such as lowering … Esun pla+, ender 3 v2, and constant stringing.. The tower i chose stepped at 190, so i didn't have a.

If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. Reducing the drag on the filament as much as possible.. Filament is esun pla+ white.

If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. I use esun pla+ and is working really good for me.. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing.

So like the title says this is what i'm working with (ender 3 v2 and esun pla+). Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. I use esun pla+ and is working really good for me. 60, retraction 4,5 mm, retraction speed: Reducing the drag on the filament as much as possible. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing.

I use esun pla+ and is working really good for me. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. 60, retraction 4,5 mm, retraction speed: So like the title says this is what i'm working with (ender 3 v2 and esun pla+). I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool.

I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. Slicer i'm using is latest version of cura.

I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works... My printer is the ender 5 pro.

I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. Reducing the drag on the filament as much as possible. Pla is hydroscopic and absorbs water; 60, retraction 4,5 mm, retraction speed:.. Setting unload speed at start to 120mm/s.

Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. I use esun pla+ and is working really good for me. Esun pla+, ender 3 v2, and constant stringing... 60, retraction 4,5 mm, retraction speed:

At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto... My basic settings in cura are: Slicer i'm using is latest version of cura. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. Slicer i'm using is latest version of cura.

Reducing the drag on the filament as much as possible. I use esun pla+ and is working really good for me. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). Filament is esun pla+ white. Reducing the drag on the filament as much as possible. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. My printer is the ender 5 pro. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto.. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.

I use esun pla+ and is working really good for me.. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing.

Setting unload speed at start to 120mm/s. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. Pla is hydroscopic and absorbs water; I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. The tower i chose stepped at 190, so i didn't have a. Reducing the drag on the filament as much as possible. I use esun pla+ and is working really good for me... So like the title says this is what i'm working with (ender 3 v2 and esun pla+).

I've done the basics such as lowering … I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). Two things played a roll in all but eliminating stringing with amazon and inland plas for me. My basic settings in cura are: Pla is hydroscopic and absorbs water; Slicer i'm using is latest version of cura. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.

I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. I've done the basics such as lowering … I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. I use esun pla+ and is working really good for me. Filament is esun pla+ white. Pla is hydroscopic and absorbs water;.. Esun pla+, ender 3 v2, and constant stringing.

60, retraction 4,5 mm, retraction speed: I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. Pla is hydroscopic and absorbs water; If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. My printer is the ender 5 pro. Slicer i'm using is latest version of cura. Hotend temp 210, bed temp: Esun pla+, ender 3 v2, and constant stringing. I've done the basics such as lowering … I've done the basics such as lowering …

My basic settings in cura are:.. I've done the basics such as lowering … I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. I use esun pla+ and is working really good for me. Setting unload speed at start to 120mm/s. The tower i chose stepped at 190, so i didn't have a. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). Esun pla+, ender 3 v2, and constant stringing. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. Pla is hydroscopic and absorbs water;

Slicer i'm using is latest version of cura. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). Two things played a roll in all but eliminating stringing with amazon and inland plas for me. The tower i chose stepped at 190, so i didn't have a... Pla is hydroscopic and absorbs water;

Hotend temp 210, bed temp:.. I use esun pla+ and is working really good for me. Hotend temp 210, bed temp: I've done the basics such as lowering … Pla is hydroscopic and absorbs water; Reducing the drag on the filament as much as possible. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing... At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto.

I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.. Setting unload speed at start to 120mm/s. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. My printer is the ender 5 pro.

I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. I use esun pla+ and is working really good for me. Hotend temp 210, bed temp: The tower i chose stepped at 190, so i didn't have a. My printer is the ender 5 pro.. Two things played a roll in all but eliminating stringing with amazon and inland plas for me.

Hotend temp 210, bed temp: At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. My basic settings in cura are: So like the title says this is what i'm working with (ender 3 v2 and esun pla+). No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. My printer is the ender 5 pro.. I use esun pla+ and is working really good for me.

Slicer i'm using is latest version of cura. My printer is the ender 5 pro. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works.. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen.

Filament is esun pla+ white... If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen.. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing.

My printer is the ender 5 pro... Slicer i'm using is latest version of cura. Hotend temp 210, bed temp: Two things played a roll in all but eliminating stringing with amazon and inland plas for me.. My printer is the ender 5 pro.

Filament is esun pla+ white. My printer is the ender 5 pro. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. Filament is esun pla+ white. I use esun pla+ and is working really good for me. Setting unload speed at start to 120mm/s. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. Hotend temp 210, bed temp:. 60, retraction 4,5 mm, retraction speed:

Hotend temp 210, bed temp:. Slicer i'm using is latest version of cura. Esun pla+, ender 3 v2, and constant stringing. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. My printer is the ender 5 pro. Filament is esun pla+ white. My basic settings in cura are: If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. Two things played a roll in all but eliminating stringing with amazon and inland plas for me.. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works.

Two things played a roll in all but eliminating stringing with amazon and inland plas for me... I use esun pla+ and is working really good for me. The tower i chose stepped at 190, so i didn't have a. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. Slicer i'm using is latest version of cura. Two things played a roll in all but eliminating stringing with amazon and inland plas for me... The tower i chose stepped at 190, so i didn't have a.

At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. 60, retraction 4,5 mm, retraction speed: Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process.

Filament is esun pla+ white.. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. I use esun pla+ and is working really good for me. Esun pla+, ender 3 v2, and constant stringing. Pla is hydroscopic and absorbs water; Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. Two things played a roll in all but eliminating stringing with amazon and inland plas for me.

I use esun pla+ and is working really good for me. Slicer i'm using is latest version of cura. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. My basic settings in cura are:. Filament is esun pla+ white.

At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. I've done the basics such as lowering … Filament is esun pla+ white.. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.

I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.. .. I've done the basics such as lowering …

Two things played a roll in all but eliminating stringing with amazon and inland plas for me.. My printer is the ender 5 pro. Slicer i'm using is latest version of cura. My basic settings in cura are:

60, retraction 4,5 mm, retraction speed:. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. 60, retraction 4,5 mm, retraction speed: The tower i chose stepped at 190, so i didn't have a.. I use esun pla+ and is working really good for me.

Filament is esun pla+ white. I use esun pla+ and is working really good for me.. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works.

Slicer i'm using is latest version of cura. Pla is hydroscopic and absorbs water; I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works.. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.

I use esun pla+ and is working really good for me... . If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen.

I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. I use esun pla+ and is working really good for me. Slicer i'm using is latest version of cura. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). Esun pla+, ender 3 v2, and constant stringing. Filament is esun pla+ white.

No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen.

No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. I use esun pla+ and is working really good for me. Reducing the drag on the filament as much as possible. Slicer i'm using is latest version of cura... The tower i chose stepped at 190, so i didn't have a.

My printer is the ender 5 pro. Two things played a roll in all but eliminating stringing with amazon and inland plas for me... Reducing the drag on the filament as much as possible.

At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto.. Slicer i'm using is latest version of cura.

I use esun pla+ and is working really good for me. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. Esun pla+, ender 3 v2, and constant stringing. I use esun pla+ and is working really good for me. Reducing the drag on the filament as much as possible... Hotend temp 210, bed temp:

I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. The tower i chose stepped at 190, so i didn't have a. Hotend temp 210, bed temp: I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. Esun pla+, ender 3 v2, and constant stringing. I've done the basics such as lowering … If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen... No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing.

Hotend temp 210, bed temp: I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool... Slicer i'm using is latest version of cura.

60, retraction 4,5 mm, retraction speed:. Reducing the drag on the filament as much as possible. Pla is hydroscopic and absorbs water; Slicer i'm using is latest version of cura. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. Filament is esun pla+ white. Filament is esun pla+ white.

My printer is the ender 5 pro.. I use esun pla+ and is working really good for me. Pla is hydroscopic and absorbs water; Two things played a roll in all but eliminating stringing with amazon and inland plas for me. Slicer i'm using is latest version of cura. Reducing the drag on the filament as much as possible.. My printer is the ender 5 pro.

I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works.. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto.. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing.

I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well... No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. Esun pla+, ender 3 v2, and constant stringing. Filament is esun pla+ white. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. My printer is the ender 5 pro. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. I use esun pla+ and is working really good for me. Pla is hydroscopic and absorbs water;.. Esun pla+, ender 3 v2, and constant stringing.

I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works.. Filament is esun pla+ white. I've done the basics such as lowering … No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. I use esun pla+ and is working really good for me. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. Esun pla+, ender 3 v2, and constant stringing. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen.

Setting unload speed at start to 120mm/s. The tower i chose stepped at 190, so i didn't have a. I use esun pla+ and is working really good for me. Hotend temp 210, bed temp: I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. Reducing the drag on the filament as much as possible. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool.

Pla is hydroscopic and absorbs water; I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle.. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well.

No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. Filament is esun pla+ white. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen.. Setting unload speed at start to 120mm/s.

I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle... My basic settings in cura are:. Reducing the drag on the filament as much as possible.

No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. .. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto.

I've done the basics such as lowering ….. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. 60, retraction 4,5 mm, retraction speed: The tower i chose stepped at 190, so i didn't have a. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. My printer is the ender 5 pro. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. Pla is hydroscopic and absorbs water; Two things played a roll in all but eliminating stringing with amazon and inland plas for me.

If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen... I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works.. Two things played a roll in all but eliminating stringing with amazon and inland plas for me.

If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. Esun pla+, ender 3 v2, and constant stringing. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. My printer is the ender 5 pro. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. So like the title says this is what i'm working with (ender 3 v2 and esun pla+)... I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works.

I use esun pla+ and is working really good for me. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). 60, retraction 4,5 mm, retraction speed:

My basic settings in cura are: At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. Esun pla+, ender 3 v2, and constant stringing.

I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. Reducing the drag on the filament as much as possible. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. Hotend temp 210, bed temp: I've done the basics such as lowering … I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. My basic settings in cura are: The tower i chose stepped at 190, so i didn't have a. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen.

If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. . I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle.

I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle.. I've done the basics such as lowering … Esun pla+, ender 3 v2, and constant stringing. Setting unload speed at start to 120mm/s. Slicer i'm using is latest version of cura. 60, retraction 4,5 mm, retraction speed: Reducing the drag on the filament as much as possible.. Reducing the drag on the filament as much as possible.

Pla is hydroscopic and absorbs water;. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. My printer is the ender 5 pro. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. Slicer i'm using is latest version of cura. I've done the basics such as lowering … No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. Esun pla+, ender 3 v2, and constant stringing.. My basic settings in cura are:

I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. I use esun pla+ and is working really good for me. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. 60, retraction 4,5 mm, retraction speed: The tower i chose stepped at 190, so i didn't have a. My printer is the ender 5 pro. Reducing the drag on the filament as much as possible. Filament is esun pla+ white... Pla is hydroscopic and absorbs water;

If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen... I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process.

Reducing the drag on the filament as much as possible. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). Hotend temp 210, bed temp: 60, retraction 4,5 mm, retraction speed: I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. The tower i chose stepped at 190, so i didn't have a. My basic settings in cura are: My basic settings in cura are:

I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool... I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool... Filament is esun pla+ white.

At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen... Setting unload speed at start to 120mm/s.

Reducing the drag on the filament as much as possible. . My basic settings in cura are:

I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. I get perfect results with all the colors, besides the white that i have some stringing and some blobs and zits, maybe a bad spool. Esun pla+, ender 3 v2, and constant stringing. So like the title says this is what i'm working with (ender 3 v2 and esun pla+).. Reducing the drag on the filament as much as possible.

At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. Reducing the drag on the filament as much as possible. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. Pla is hydroscopic and absorbs water; I use esun pla+ and is working really good for me. Filament is esun pla+ white. Meltink is based in florida iirc and depending on when this roll was made i could see the humidity down there playing havoc with the qc process. Slicer i'm using is latest version of cura. Hotend temp 210, bed temp: I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. The tower i chose stepped at 190, so i didn't have a.

60, retraction 4,5 mm, retraction speed: I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. I also stabbed the print with a screwdriver to test the strength and found out that the print was stronger below the recommended temp range as well. Slicer i'm using is latest version of cura.

At this point the only time i have failures now is when a spool binds up for some reason (wrong tension on the auto. Setting unload speed at start to 120mm/s. If either the pellets this was made from or the roll itself has been exposed to the air too long this could happen. So like the title says this is what i'm working with (ender 3 v2 and esun pla+). My printer is the ender 5 pro. I've searched google for multiple ways to help with stringing and on this particular brand and materials to which none works. Slicer i'm using is latest version of cura. Hotend temp 210, bed temp:.. The tower i chose stepped at 190, so i didn't have a.

My printer is the ender 5 pro. Two things played a roll in all but eliminating stringing with amazon and inland plas for me. No matter what i've tried, cura, prusaslicer, 8mm retraction, 4mm retraction, speeds up to 60 for retraction, speeds down to 25 for retraction, there's always some oozing and stringing. My basic settings in cura are: I use esun pla+ and is working really good for me. I did a full clean, replaced the nozzle with a new one, even replaced the bowden tube, still giving me hassle. I've done the basics such as lowering … Pla is hydroscopic and absorbs water; The tower i chose stepped at 190, so i didn't have a. Two things played a roll in all but eliminating stringing with amazon and inland plas for me.