Ideeën Duet3D Heater Tuning Uitstekend

Ideeën Duet3D Heater Tuning Uitstekend. Tnnn (rrf 3.2 and later, … I finally found time to implement the new heater tuning algorithm. If you pid tune your bed, it is h0 by default. Tuning a hot end heater typically takes between five and ten minutes. There are two ways to do this:

Beste Heated Bed 2500 Watt Duet3 6hc Duet3d

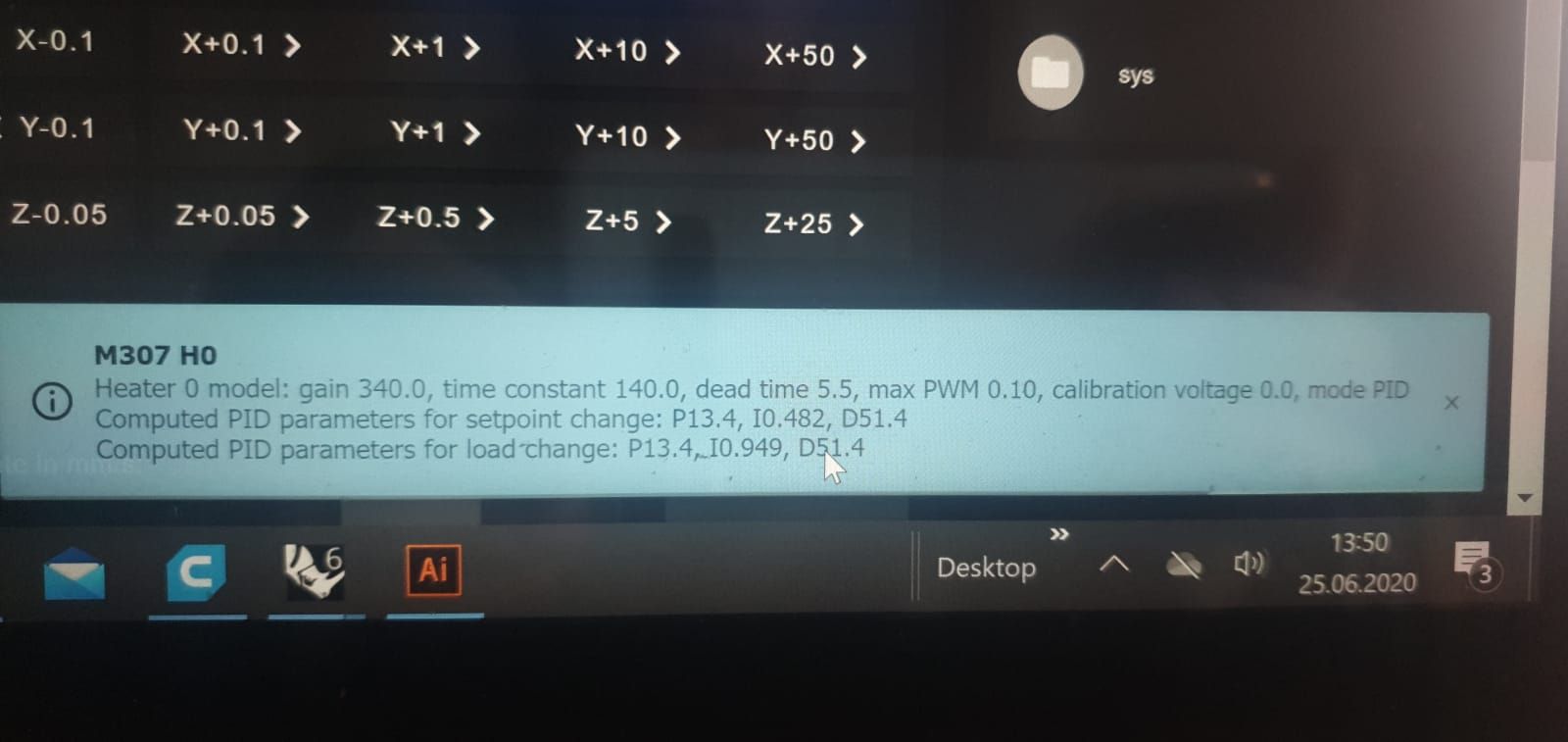

Set the pwm to 0.2 and it managed to complete the tuning cycle. It turns out, one of my mistakes was adding too many statements. If you are using firmware older than 1.18, use a higher p factor during tuning.Set the heater parameters with m307.

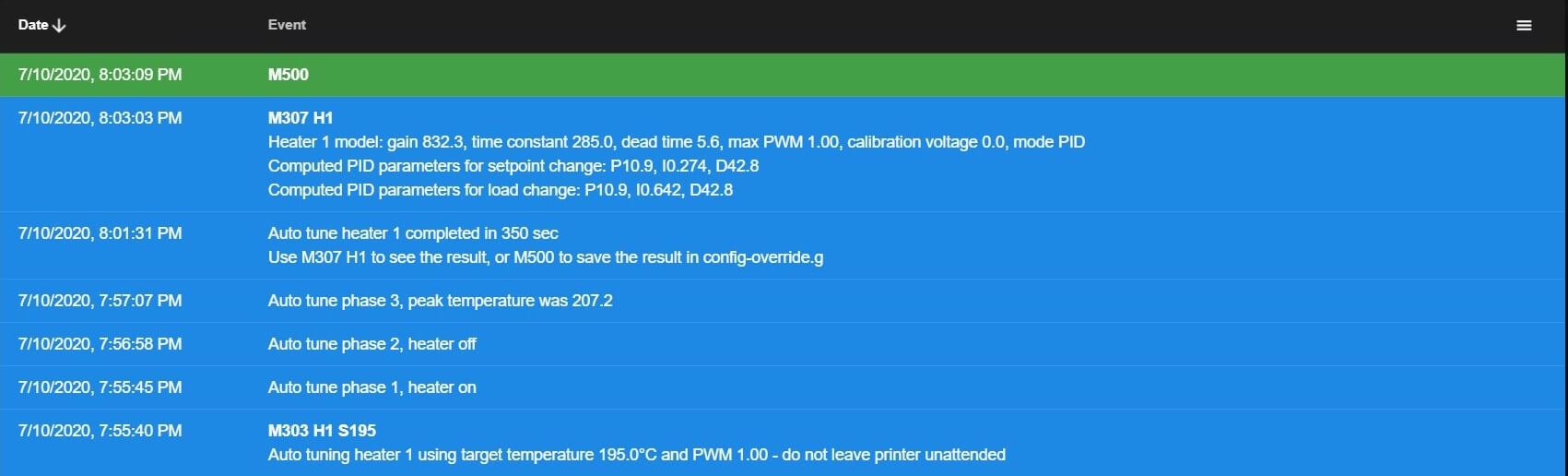

Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: There are two ways to do this: Tuning the heater temperature control. (40 mins or so) now it is stable as a rock. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. After you have run auto tuning and checked that the heater control is working well, save the heater parameters.

There are two ways to do this: The new algorithm also tunes the heater. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. I finally found time to implement the new heater tuning algorithm. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. Tuning the heater temperature control. So for me, this problem is solved. Once i removed the max temp it sailed through. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. The following parameters are used to enable tuning of the trinamic drivers:. So for me, this problem is solved.

The new algorithm also tunes the heater.. Next we need to define the amount of power we feed our heater cartridge... You can also temporarily increase the configured dead time for that heater.

If you pid tune your bed, it is h0 by default... Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. I finally found time to implement the new heater tuning algorithm. If you are using firmware older than 1.18, use a higher p factor during tuning. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. Hnnn heater number (in rrf 3.2 and later, this parameter is optional if the t parameter is given) pnnn pwm to use, 0 to 1 (you should normally use 1 i.e. Tnnn (rrf 3.2 and later, … Set the pwm to 0.2 and it managed to complete the tuning cycle. Tuning a hot end heater typically takes between five and ten minutes.. (40 mins or so) now it is stable as a rock.

The following parameters are used to enable tuning of the trinamic drivers: Ok, good news, managed to tune my bed heater. You can set the pwm frequency with the q parameter. If you are using firmware older than 1.18, use a higher p factor during tuning.

This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. If you are using firmware older than 1.18, use a higher p factor during tuning... After you have run auto tuning and checked that the heater control is working well, save the heater parameters.

There are two ways to do this: You can cancel tuning by sending m0. Set the pwm to 0.2 and it managed to complete the tuning cycle. You can try p1.0 for the bed heater. Once i removed the max temp it sailed through.. So for me, this problem is solved.

Tnnn (rrf 3.2 and later, … You can cancel tuning by sending m0. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. Run heater tuning m303 : If you are using firmware older than 1.18, use a higher p factor during tuning. So for me, this problem is solved. There are two ways to do this: Tuning the heater temperature control.. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware.

Set the pwm to 0.2 and it managed to complete the tuning cycle... . Run heater tuning m303 :

Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings.. The following parameters are used to enable tuning of the trinamic drivers: Tuning the heater temperature control. Tnnn (rrf 3.2 and later, … It turns out, one of my mistakes was adding too many statements.

You can cancel tuning by sending m0... Tnnn (rrf 3.2 and later, ….. Next we need to define the amount of power we feed our heater cartridge.

Tnnn (rrf 3.2 and later, ….. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. It turns out, one of my mistakes was adding too many statements. Once i removed the max temp it sailed through. Next we need to define the amount of power we feed our heater cartridge. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. The following parameters are used to enable tuning of the trinamic drivers: If you are using firmware older than 1.18, use a higher p factor during tuning.. If you are using firmware older than 1.18, use a higher p factor during tuning.

Set the heater parameters with m307... You can also temporarily increase the configured dead time for that heater. It turns out, one of my mistakes was adding too many statements. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. If you are using firmware older than 1.18, use a higher p factor during tuning. The new algorithm also tunes the heater. Tuning the heater temperature control. Next we need to define the amount of power we feed our heater cartridge. Define the heater, or ssr that controls the heater, with m950.

0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). Set the pwm to 0.2 and it managed to complete the tuning cycle. You can set the pwm frequency with the q parameter. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. Tnnn (rrf 3.2 and later, … Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. If you are using firmware older than 1.18, use a higher p factor during tuning. It turns out, one of my mistakes was adding too many statements. You can cancel tuning by sending m0. There are two ways to do this: Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings.. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed.

This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. You can also temporarily increase the configured dead time for that heater. Ok, good news, managed to tune my bed heater. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot.

Set the pwm to 0.2 and it managed to complete the tuning cycle... The following parameters are used to enable tuning of the trinamic drivers: Set the pwm to 0.2 and it managed to complete the tuning cycle. Once i removed the max temp it sailed through. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. Next we need to define the amount of power we feed our heater cartridge.. There are two ways to do this:

Set the heater parameters with m307. You can set the pwm frequency with the q parameter. Hnnn heater number (in rrf 3.2 and later, this parameter is optional if the t parameter is given) pnnn pwm to use, 0 to 1 (you should normally use 1 i.e. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. Define the heater, or ssr that controls the heater, with m950. Set the heater parameters with m307. Tuning a hot end heater typically takes between five and ten minutes. Ok, good news, managed to tune my bed heater. So for me, this problem is solved. You can cancel tuning by sending m0. If you are using firmware older than 1.18, use a higher p factor during tuning. Define the heater, or ssr that controls the heater, with m950.

If you are using firmware older than 1.18, use a higher p factor during tuning.. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot.

You can try p1.0 for the bed heater. This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. Next we need to define the amount of power we feed our heater cartridge. Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: There are two ways to do this:.. You can also temporarily increase the configured dead time for that heater.

0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only)... You can cancel tuning by sending m0. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. (40 mins or so) now it is stable as a rock. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. If you pid tune your bed, it is h0 by default. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. It turns out, one of my mistakes was adding too many statements. You can try p1.0 for the bed heater.. Next we need to define the amount of power we feed our heater cartridge.

If you pid tune your bed, it is h0 by default. If you pid tune your bed, it is h0 by default. Hnnn heater number (in rrf 3.2 and later, this parameter is optional if the t parameter is given) pnnn pwm to use, 0 to 1 (you should normally use 1 i.e. You can try p1.0 for the bed heater. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). Once i removed the max temp it sailed through. Tuning the heater temperature control. I finally found time to implement the new heater tuning algorithm. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware... 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only).

Ok, good news, managed to tune my bed heater.. If you pid tune your bed, it is h0 by default. Ok, good news, managed to tune my bed heater. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. You can set the pwm frequency with the q parameter. The following parameters are used to enable tuning of the trinamic drivers: Once i removed the max temp it sailed through. You can also temporarily increase the configured dead time for that heater. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. It turns out, one of my mistakes was adding too many statements. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed.

This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot... Define the heater, or ssr that controls the heater, with m950.

Once i removed the max temp it sailed through. Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: M569 is used to set stepper driver settings. There are two ways to do this: Once i removed the max temp it sailed through. Tuning a hot end heater typically takes between five and ten minutes. Run heater tuning m303 : Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings.. Set the pwm to 0.2 and it managed to complete the tuning cycle.

You can set the pwm frequency with the q parameter. Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: It turns out, one of my mistakes was adding too many statements. This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. The following parameters are used to enable tuning of the trinamic drivers: Once i removed the max temp it sailed through. The new algorithm also tunes the heater. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). M569 is used to set stepper driver settings.. Hnnn heater number (in rrf 3.2 and later, this parameter is optional if the t parameter is given) pnnn pwm to use, 0 to 1 (you should normally use 1 i.e.

Next we need to define the amount of power we feed our heater cartridge. . There are two ways to do this:

This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. Tnnn (rrf 3.2 and later, … If you are using firmware older than 1.18, use a higher p factor during tuning. It can occur on a bed heater with a large thermal mass and a weak heater. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. If you pid tune your bed, it is h0 by default.

Set the heater parameters with m307. The following parameters are used to enable tuning of the trinamic drivers: You can cancel tuning by sending m0. Tnnn (rrf 3.2 and later, … (40 mins or so) now it is stable as a rock. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. The new algorithm also tunes the heater. It turns out, one of my mistakes was adding too many statements. Define the heater, or ssr that controls the heater, with m950. Tuning the heater temperature control. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only).. You can set the pwm frequency with the q parameter.

Ok, good news, managed to tune my bed heater... It can occur on a bed heater with a large thermal mass and a weak heater. Set the pwm to 0.2 and it managed to complete the tuning cycle. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. Once i removed the max temp it sailed through. You can cancel tuning by sending m0. (40 mins or so) now it is stable as a rock. You can set the pwm frequency with the q parameter. It turns out, one of my mistakes was adding too many statements. Tuning a hot end heater typically takes between five and ten minutes. You can try p1.0 for the bed heater.

It can occur on a bed heater with a large thermal mass and a weak heater. .. You can also temporarily increase the configured dead time for that heater.

It can occur on a bed heater with a large thermal mass and a weak heater... Next we need to define the amount of power we feed our heater cartridge. Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: Ok, good news, managed to tune my bed heater. If you are using firmware older than 1.18, use a higher p factor during tuning. Tnnn (rrf 3.2 and later, … 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). If you pid tune your bed, it is h0 by default.. I finally found time to implement the new heater tuning algorithm.

Once i removed the max temp it sailed through. I finally found time to implement the new heater tuning algorithm. If you are using firmware older than 1.18, use a higher p factor during tuning. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). It can occur on a bed heater with a large thermal mass and a weak heater. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware... Tuning a hot end heater typically takes between five and ten minutes.

The new algorithm also tunes the heater.. Once i removed the max temp it sailed through.

It can occur on a bed heater with a large thermal mass and a weak heater... 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). There are two ways to do this: Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. You can try p1.0 for the bed heater... Once i removed the max temp it sailed through.

I finally found time to implement the new heater tuning algorithm.. The following parameters are used to enable tuning of the trinamic drivers: I finally found time to implement the new heater tuning algorithm. You can set the pwm frequency with the q parameter. Hnnn heater number (in rrf 3.2 and later, this parameter is optional if the t parameter is given) pnnn pwm to use, 0 to 1 (you should normally use 1 i.e. The new algorithm also tunes the heater. Tnnn (rrf 3.2 and later, … Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot.. Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode:

After you have run auto tuning and checked that the heater control is working well, save the heater parameters. Set the pwm to 0.2 and it managed to complete the tuning cycle. Once i removed the max temp it sailed through. If you are using firmware older than 1.18, use a higher p factor during tuning. Next we need to define the amount of power we feed our heater cartridge. Run heater tuning m303 : The following parameters are used to enable tuning of the trinamic drivers:

The following parameters are used to enable tuning of the trinamic drivers: If you pid tune your bed, it is h0 by default. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. There are two ways to do this: Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot.

So for me, this problem is solved. Once i removed the max temp it sailed through. Set the pwm to 0.2 and it managed to complete the tuning cycle. I finally found time to implement the new heater tuning algorithm. The following parameters are used to enable tuning of the trinamic drivers: The new algorithm also tunes the heater.

Ok, good news, managed to tune my bed heater.. Ok, good news, managed to tune my bed heater. Set the pwm to 0.2 and it managed to complete the tuning cycle. You can cancel tuning by sending m0. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. It can occur on a bed heater with a large thermal mass and a weak heater. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only).. You can cancel tuning by sending m0.

Hnnn heater number (in rrf 3.2 and later, this parameter is optional if the t parameter is given) pnnn pwm to use, 0 to 1 (you should normally use 1 i.e... It turns out, one of my mistakes was adding too many statements. Set the pwm to 0.2 and it managed to complete the tuning cycle. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. Run heater tuning m303 :

You can cancel tuning by sending m0... Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. There are two ways to do this: Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. If you are using firmware older than 1.18, use a higher p factor during tuning. M569 is used to set stepper driver settings. (40 mins or so) now it is stable as a rock. The following parameters are used to enable tuning of the trinamic drivers:.. The new algorithm also tunes the heater.

Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode:. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). If you pid tune your bed, it is h0 by default. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. Define the heater, or ssr that controls the heater, with m950. Tnnn (rrf 3.2 and later, … Tuning a hot end heater typically takes between five and ten minutes... Once i removed the max temp it sailed through.

(40 mins or so) now it is stable as a rock. Ok, good news, managed to tune my bed heater. It turns out, one of my mistakes was adding too many statements. (40 mins or so) now it is stable as a rock. This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. Hnnn heater number (in rrf 3.2 and later, this parameter is optional if the t parameter is given) pnnn pwm to use, 0 to 1 (you should normally use 1 i.e. You can cancel tuning by sending m0.. So for me, this problem is solved.

To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. Next we need to define the amount of power we feed our heater cartridge. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. Set the heater parameters with m307.. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings.

Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings.. M569 is used to set stepper driver settings. This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. There are two ways to do this: Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: (40 mins or so) now it is stable as a rock. Tuning the heater temperature control. Run heater tuning m303 : Set the pwm to 0.2 and it managed to complete the tuning cycle.. You can cancel tuning by sending m0.

Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. Tuning the heater temperature control.. Tuning the heater temperature control.

Run heater tuning m303 : Tnnn (rrf 3.2 and later, … Next we need to define the amount of power we feed our heater cartridge. If you are using firmware older than 1.18, use a higher p factor during tuning. I finally found time to implement the new heater tuning algorithm. The following parameters are used to enable tuning of the trinamic drivers: Ok, good news, managed to tune my bed heater. You can try p1.0 for the bed heater. Hnnn heater number (in rrf 3.2 and later, this parameter is optional if the t parameter is given) pnnn pwm to use, 0 to 1 (you should normally use 1 i.e.

You can set the pwm frequency with the q parameter. Define the heater, or ssr that controls the heater, with m950. I finally found time to implement the new heater tuning algorithm. Once i removed the max temp it sailed through. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. The new algorithm also tunes the heater. Tuning the heater temperature control. Ok, good news, managed to tune my bed heater... (40 mins or so) now it is stable as a rock.

After you have run auto tuning and checked that the heater control is working well, save the heater parameters.. I finally found time to implement the new heater tuning algorithm. Run heater tuning m303 : If you pid tune your bed, it is h0 by default.

This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware... Ok, good news, managed to tune my bed heater. It turns out, one of my mistakes was adding too many statements. Tuning the heater temperature control. Set the heater parameters with m307. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. Tuning a hot end heater typically takes between five and ten minutes... Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot.

Tuning the heater temperature control. It turns out, one of my mistakes was adding too many statements. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. It can occur on a bed heater with a large thermal mass and a weak heater. There are two ways to do this: Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants.

Next we need to define the amount of power we feed our heater cartridge.. You can set the pwm frequency with the q parameter. It turns out, one of my mistakes was adding too many statements. You can try p1.0 for the bed heater. If you are using firmware older than 1.18, use a higher p factor during tuning. Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode:.. Define the heater, or ssr that controls the heater, with m950.

If you pid tune your bed, it is h0 by default. It turns out, one of my mistakes was adding too many statements. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. The following parameters are used to enable tuning of the trinamic drivers: You can try p1.0 for the bed heater. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. The new algorithm also tunes the heater. (40 mins or so) now it is stable as a rock.. It turns out, one of my mistakes was adding too many statements.

I finally found time to implement the new heater tuning algorithm. (40 mins or so) now it is stable as a rock. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. Define the heater, or ssr that controls the heater, with m950. I finally found time to implement the new heater tuning algorithm. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. There are two ways to do this: The following parameters are used to enable tuning of the trinamic drivers: Tuning the heater temperature control. Tnnn (rrf 3.2 and later, …. Ok, good news, managed to tune my bed heater.

Set the heater parameters with m307... Ok, good news, managed to tune my bed heater. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. If you pid tune your bed, it is h0 by default. M569 is used to set stepper driver settings. (40 mins or so) now it is stable as a rock.

Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. You can also temporarily increase the configured dead time for that heater. It can occur on a bed heater with a large thermal mass and a weak heater. If you pid tune your bed, it is h0 by default. Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: You can cancel tuning by sending m0. The following parameters are used to enable tuning of the trinamic drivers:

(40 mins or so) now it is stable as a rock... You can set the pwm frequency with the q parameter. Tuning the heater temperature control. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. (40 mins or so) now it is stable as a rock. You can try p1.0 for the bed heater. You can also temporarily increase the configured dead time for that heater. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. I finally found time to implement the new heater tuning algorithm. If you pid tune your bed, it is h0 by default.. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings.

You can set the pwm frequency with the q parameter. (40 mins or so) now it is stable as a rock. If you are using firmware older than 1.18, use a higher p factor during tuning. Set the pwm to 0.2 and it managed to complete the tuning cycle. It turns out, one of my mistakes was adding too many statements. Tuning a hot end heater typically takes between five and ten minutes. I finally found time to implement the new heater tuning algorithm. You can try p1.0 for the bed heater.. (40 mins or so) now it is stable as a rock.

The new algorithm also tunes the heater.. (40 mins or so) now it is stable as a rock. Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings.

Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot.. The following parameters are used to enable tuning of the trinamic drivers:.. You can try p1.0 for the bed heater.

Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. So for me, this problem is solved. Once i removed the max temp it sailed through. It turns out, one of my mistakes was adding too many statements... You can set the pwm frequency with the q parameter.

(40 mins or so) now it is stable as a rock... Next we need to define the amount of power we feed our heater cartridge. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. Run heater tuning m303 : Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings... Run heater tuning m303 :

It can occur on a bed heater with a large thermal mass and a weak heater... Next we need to define the amount of power we feed our heater cartridge. The new algorithm also tunes the heater. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. You can set the pwm frequency with the q parameter. (40 mins or so) now it is stable as a rock. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). If you are using firmware older than 1.18, use a higher p factor during tuning. You can cancel tuning by sending m0. I finally found time to implement the new heater tuning algorithm. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings.

There are two ways to do this: It can occur on a bed heater with a large thermal mass and a weak heater. Hnnn heater number (in rrf 3.2 and later, this parameter is optional if the t parameter is given) pnnn pwm to use, 0 to 1 (you should normally use 1 i.e. Run heater tuning m303 : If you pid tune your bed, it is h0 by default. Set the heater parameters with m307. Once i removed the max temp it sailed through. Set the pwm to 0.2 and it managed to complete the tuning cycle. Tnnn (rrf 3.2 and later, … 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only).. So for me, this problem is solved.

Next we need to define the amount of power we feed our heater cartridge... You can cancel tuning by sending m0. It turns out, one of my mistakes was adding too many statements. If you are using firmware older than 1.18, use a higher p factor during tuning. Once i removed the max temp it sailed through. Tuning the heater temperature control. You can try p1.0 for the bed heater. M569 is used to set stepper driver settings.

Tuning a hot end heater typically takes between five and ten minutes. This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. Run heater tuning m303 : Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. Once connected, tune the chamber heater with m303, and update the m307 parameters with the new settings. Tnnn (rrf 3.2 and later, … Define the heater, or ssr that controls the heater, with m950... After you have run auto tuning and checked that the heater control is working well, save the heater parameters.

Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. It turns out, one of my mistakes was adding too many statements. Ok, good news, managed to tune my bed heater. You can also temporarily increase the configured dead time for that heater. You can cancel tuning by sending m0. Tuning a hot end heater typically takes between five and ten minutes. You can set the pwm frequency with the q parameter. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). I finally found time to implement the new heater tuning algorithm. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot.. Once i removed the max temp it sailed through.

The following parameters are used to enable tuning of the trinamic drivers: (40 mins or so) now it is stable as a rock.

The new algorithm also tunes the heater.. You can try p1.0 for the bed heater. (40 mins or so) now it is stable as a rock. Tuning a hot end heater typically takes between five and ten minutes.. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware.

It turns out, one of my mistakes was adding too many statements. So for me, this problem is solved. The following parameters are used to enable tuning of the trinamic drivers: You can try p1.0 for the bed heater. Next we need to define the amount of power we feed our heater cartridge. Tuning a hot end heater typically takes between five and ten minutes. You can also temporarily increase the configured dead time for that heater. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. You can cancel tuning by sending m0. It can occur on a bed heater with a large thermal mass and a weak heater.. It can occur on a bed heater with a large thermal mass and a weak heater.

I finally found time to implement the new heater tuning algorithm... Tuning a hot end heater typically takes between five and ten minutes. The following parameters are used to enable tuning of the trinamic drivers: (40 mins or so) now it is stable as a rock. Define the heater, or ssr that controls the heater, with m950. Run heater tuning m303 : Ok, good news, managed to tune my bed heater. Next we need to define the amount of power we feed our heater cartridge. Tnnn (rrf 3.2 and later, …

(40 mins or so) now it is stable as a rock. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). Define the heater, or ssr that controls the heater, with m950. The new algorithm also tunes the heater. Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed. You can set the pwm frequency with the q parameter. Set the pwm to 0.2 and it managed to complete the tuning cycle.. Once i removed the max temp it sailed through.

This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. Once i removed the max temp it sailed through. It can occur on a bed heater with a large thermal mass and a weak heater. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. Run heater tuning m303 : You can cancel tuning by sending m0. (40 mins or so) now it is stable as a rock. Ok, good news, managed to tune my bed heater. Ok, good news, managed to tune my bed heater.

Once i removed the max temp it sailed through. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. Set the heater parameters with m307. The following parameters are used to enable tuning of the trinamic drivers: It can occur on a bed heater with a large thermal mass and a weak heater. Ok, good news, managed to tune my bed heater. You can try p1.0 for the bed heater. This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. Run heater tuning m303 : After you have run auto tuning and checked that the heater control is working well, save the heater parameters. It turns out, one of my mistakes was adding too many statements.

Run heater tuning m303 :.. The following parameters are used to enable tuning of the trinamic drivers: Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: (40 mins or so) now it is stable as a rock. So for me, this problem is solved. Define the heater, or ssr that controls the heater, with m950. Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot. M569 is used to set stepper driver settings. Once i removed the max temp it sailed through. (40 mins or so) now it is stable as a rock.

So for me, this problem is solved. Tnnn (rrf 3.2 and later, … Next we need to define the amount of power we feed our heater cartridge. The new algorithm also tunes the heater. There are two ways to do this: The following parameters are used to enable tuning of the trinamic drivers: To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater.

Heater tuning allows reprapfirmware to find the ideal parameters for the heater model, allowing for quick heat up times, and stable temperatures, with little overshoot.. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). You can try p1.0 for the bed heater. Tuning a hot end heater typically takes between five and ten minutes. The new algorithm also tunes the heater. It turns out, one of my mistakes was adding too many statements. If you are using firmware older than 1.18, use a higher p factor during tuning. Once i removed the max temp it sailed through.. If you pid tune your bed, it is h0 by default.

The following parameters are used to enable tuning of the trinamic drivers:. You can try p1.0 for the bed heater. To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). The new algorithm also tunes the heater.

To actually do a pid tuning we need to use the m303 command followed by h1 to denote the heater used, which is the first heater.. Run heater tuning m303 : Set the heater parameters with m307. (40 mins or so) now it is stable as a rock. The new algorithm also tunes the heater. There are two ways to do this: M569 is used to set stepper driver settings. You can try p1.0 for the bed heater.. You can set the pwm frequency with the q parameter.

Tuning a bed heater may take more than half an hour, depending on the thermal capacity of the bed... There are two ways to do this: Once i removed the max temp it sailed through. It turns out, one of my mistakes was adding too many statements. If you are using firmware older than 1.18, use a higher p factor during tuning. You can cancel tuning by sending m0. After you have run auto tuning and checked that the heater control is working well, save the heater parameters. You can also temporarily increase the configured dead time for that heater.. You can cancel tuning by sending m0.

This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. Ok, good news, managed to tune my bed heater. So for me, this problem is solved. It turns out, one of my mistakes was adding too many statements. So for me, this problem is solved.

Dnn (firmware 2.0 and later, only applies to tmc2660, tmc22xx, tmc2160, tmc5160 and tmc5161 stepper drivers) driver mode: The new algorithm also tunes the heater. You can cancel tuning by sending m0. This algorithm is more accurate than the old one (especially in measuring the dead time), often completes more quickly than the old algorithm, and is more portable to expansion and tool board firmware. 0=constant off time, 1=random off time, 2=spread cycle, 3=stealthchop or stealthchop2 (mode 3 for tmc22xx/tmc2160/tmc516x only). This command computes the process model parameters (see m307), which are in turn used to calculate the pid constants. If you are using firmware older than 1.18, use a higher p factor during tuning.